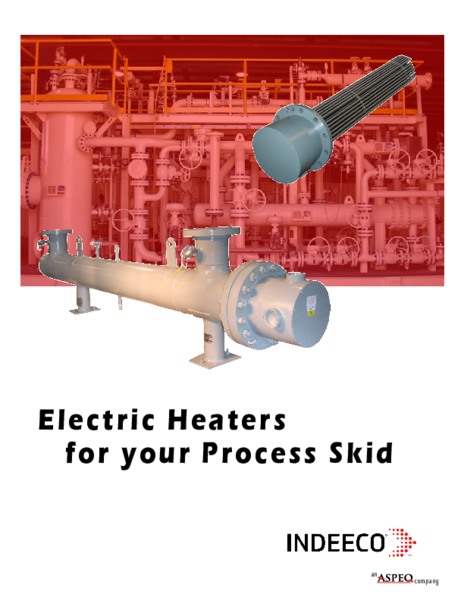

Process Skid Heating

The process skid industry is highly competitive and time-sensitive. Customers demand clear cost estimates and fast delivery for custom solutions. Indeeco is ready to rise to that challenge. As a trusted solutions partner since 1929, we leverage deep expertise to offer valuable design improvements that can optimize performance, reduce footprint, and lower overall costs.

Standard Features

Our designs are based on proven performance. Skid mounting is available with prewired configuration.

Flexible Lead Times

You need it, and you need it now. Indeeco makes custom products, and our manufacturing process is flexible enough to accommodate varying delivery requests.

For example: A manufacturer in Arkansas had their entire line go down when they lost six custom 5″ flanged immersion heaters. Their normal supplier’s best delivery offer was four weeks. Facing great economic impact, they contacted Indeeco and expressed the urgency. Indeeco offered expedited delivery not to exceed two weeks. We received a verbal commitment, delivered two units in three days and the remaining four eight days later!

Cartridge Type Defrost Heaters

Quick Price Quotes

Just because you need it now doesn’t mean you can pay any price. Our quotes are accurate, quick, and economical. We understand the pressure you are under and the time constraints you face. Our proprietary pricing software allows us to provide you with a quote and specification sheet on some products in a matter of minutes.

Your advantages are a quick turnaround, competitive pricing, and assurance that the quote you receive is customized for your specific application.

Custom Solutions

Customization is our standard offering. And when designing more complex solutions, our proprietary design software allows us to provide you with the valuable engineering information you require.

Your advantages are standard pricing with all the benefits of customization, solutions designed with your unique application in mind, quality products manufactured by a company whose focus is cusomization, and standard delivery on custom solutions.

Pipe Thread Heaters

Voltages up to 600V

1″, 1-1/4″, 2″, 2-1/2″ and 3″ NPT

Stainless Steel, Brass, or Steel fittings

Elements typically Incoloy, SST, Copper, or Steel

Built-in thermostats available

UL, CSA, and CE listings available

NEMA 1, 4, 4X, and 7 terminal enclosures

Flange Heaters

Voltages up to 600V

Process temperatures up to 1200F

Pressure ratings up to 3000 PSI

Flange sizes up to 36″ and 2500# ASME B16.5

Built-in thermostats available

Thermocouples available

ASME code stamp is optional

NEMA 1, 4, 4X, and 7 terminal enclosures

Circulation Heaters

Voltages up to 600V

Outlet temperatures up to 1200F

Pressure ratings up to 3000 PSI

Built-in thermostats available

Thermocouples available

Vessel diameters up to 36″

ASME code stamp is optional

NEMA 1, 4, 4X, and 7 terminal enclosures

Control Panels

Indeeco can provide a control system for any electric process heating application. Standard and custom sized enclosures, along with custom designed control operation, give Indeeco the flexibility to supply a wide range of remote, built-on or skid-mounted control panels to complete the heater control system.

Indeeco offers two standard control panel designs: Fully proportional SCR control and On/Off contactor control.

A Vernier control panel can also be supplied. Vernier control utilizes contactors, one SCR controller, and a microprocessor based sequencer. The sequencer controls the staging of the contactors and the SCR controller. The SCR controller serves to fill in the gaps between the step-controlled stages.