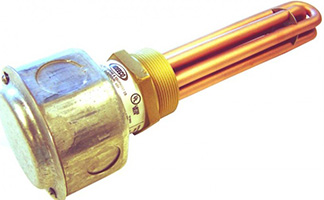

Screw Plug Immersion Heaters

Indeeco’s screw plug immersion heaters offer durable, efficient heating solutions for a wide variety of industrial and commercial applications. Available in pipe thread sizes from 1″ to 3″ NPT, these heaters can be ordered from stock configurations or fully customized to meet your specific process needs.

Engineered for performance and longevity, Indeeco heaters include features that ensure safety, consistent heat distribution, and easy installation. Most designs are also available with Indeeco’s FastTrack program for accelerated delivery.

Key Features:

- 1″ to 3″ NPT screw plug sizes available

- Uniform element bends maintain insulation integrity and electrical reliability

- One-piece forged hex, thread, and riser for rugged, leak-resistant performance

- Element spacers reduce risk of hot spots and extend element life

- Encapsulated bussing with epoxy seal ensures permanent electrical connections

- UL & CSA labeled for all standard copper, stainless steel, and Incoloy elements

- Suitable for NEMA 1, 4, and 4X environments (indoor/outdoor, washdown, corrosive areas)

Approvals

Standard Features

Tubular Elements

Welded or silver soldered into a hex head pipe thread fitting. Elements have 80/20 nickel-chromium resistance coils centered in a heavy gauge metal tube surrounded by magnesium oxide insulation. Through rolling, the magnesium oxide is packed to a rock-like density for rapid heat transfer from the coil to the sheath

Pipe Thread Fittings

Forged brass fittings, silver soldered to the sheath, are furnished as standard with copper sheathed heaters. Steel and stainless steel sheathed elements are welded into fittings of like material.

Enclosures

Available in NEMA 1, 4, 4X, and 7 terminal enclosures

Built-In Thermostats

Provide automatic temperature control without the necessity of installing a separate well for the thermostat bulb in the field and making electrical connections between the heater and control.

Element Spacers

Made from Type 304 stainless steel to maintain a uniform distance between elements, thus preventing hot spots.

Epoxy Seals

A moisture-resistant seal where fluid temperatures do not exceed 250° F.

Applications

Water Heating

Oil Heating

Air Heating

Heat Transfer Systems

Food Processing

Boiler Equipment

Parts Washing Tanks