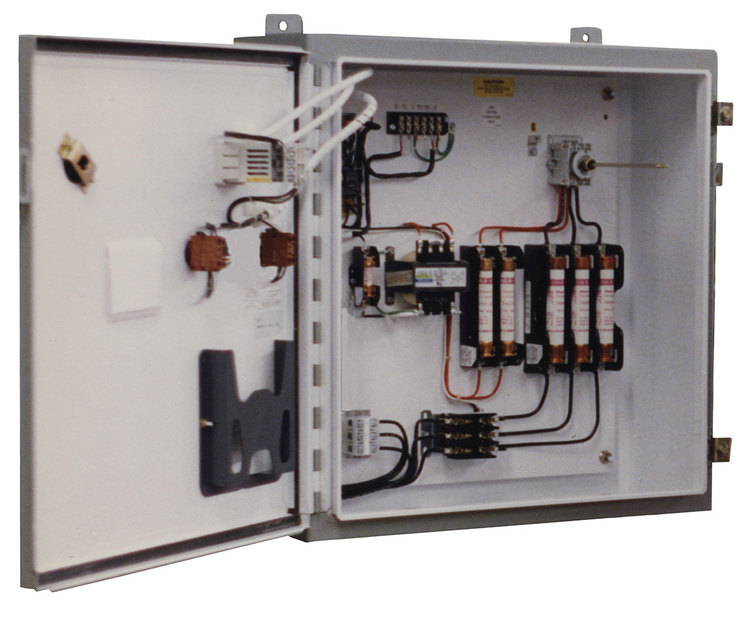

870 Series Contactor Control Panel

The Indeeco 870 Series Contactor Temperature Control Panel offers reliable ON/OFF process temperature control and is ideal for applications that do not require precise temperature regulation. Engineered for industrial use, this panel is a dependable, cost-effective choice for resistive load control in both indoor and outdoor environments.

For systems requiring two or more heating stages, the panel incorporates an electronic sequencer (step controller) driven by a proportional output temperature controller. This setup minimizes load cycling and improves overall temperature stability, even in applications with moderate control requirements.

The 870 Series panel comes completely assembled, pre-wired, and factory-tested, ensuring quick installation and trouble-free startup.

Approvals

Standard Features

UL Listed/CSA Approved

NEMA 4/12 Painted Steel Enclosure1

PID self-tuning temperature controller (adjustable process temperature with standard type “J” thermo-couple input)

Over-temperature controller (adjustable temperature limit with standard type “K” thermocouple input)

Disconnecting 50 Amp contactor for resistive loads (per circuit)

120 VAC control power transformer with primary and secondary fusing

Power circuit fusing

Microprocessor-based sequencer (for panels with two or more heating stages)

Door interlocking disconnect switch

Manual reset pushbutton with built-in pilot light (red) for “OVER-TEMPERATURE” alarm

Selector Switch – ON/OFF with built-in pilot light (green) for “POWER ON” indication

Terminals for customer supplied remote interlock

Wiring diagram permanently affixed to the inside of the cover

Short Circuit Current Rating of 5 KA

Optional Features

Control Relays

These relays are activated by safety devices, such as a flow switch or remote shutoff.

Indicator Lights

Additional indicator lights may be specified for visual indication of system status, such as “LOW TEMPERATURE”.

Audible Alarm Package

Includes a horn, pilot light, latching relay and a push button for silencing the horn.

Low Liquid Cutoff

The relay is mounted and wired with sensing probe shipped loose for field installation.

Motor Starter

This package consists of a motor starter for pump motor start-up. Motor starter is internally mounted and field connected to the pump motor.

Special Controllers

The customer may specify the use of special process or over-temperature controllers for a different temperature range, sensor input, control mode, etc.

Panel Heater

A heater and thermostat are provided to prevent condensation and maintain minimum ambient temperature for electrical components.

Wire Markers

Identification markers are attached to both ends of all control and power wires.

Tagging of Internal Parts

Permanent tags are attached to the subpanel near internal parts and marked with component titles as noted on the wiring diagram.

Explosion-Resistant Panel

A cast aluminum enclosure is rated for Class I, Groups C & D and Class II, Groups E, F & G (NEMA 7, 9).

Purged Panels

Type Z for Class I, Division 2 areas Type X for Class I, Division 1 areas.

Optional Temperature Inputs

Type “K” thermocouple inputs or “RTD” inputs.

Stainless Steel Panel Enclosure (NEMA 4X)

This con-struction provides extra corrosion resistance for harsh environments1.

(1) Agency listed for NEMA 4 only.

Special Ratings

65 KA interupting amp rating